A Shore Hardness Durometer is an instrument consisting of a precisely machined indenter, calibrated spring, pressure foot and display (analogue or digital) used to measure the hardness of a material. When the indenter is pressed into a material under certain conditions, a Shore hardness value is determined which is the reciprocal of the penetration depth of the indenter.

In this article we explain how well measuring shore hardness works with the PosiTector SHD Shore Hardness Durometer. The PosiTector SHD shore hardness durometer is designed for testing the hardness of non-metallic materials such as soft rubber, hard plastic and very soft gels. It features an easy-to-read digital display, internal memory, and a user-settable measurement timer with on-screen countdown.

What is material hardness?

Material hardness is a measure of a material's ability to resist deformation such as bending, scratching, abrasion or cutting. Measuring strength and durability is a critical element of quality assurance and quality control. A material often has to meet a specific hardness standard, which is often determined by testing the shore hardness.

Indentation hardness testers such as the PosiTector SHD Shore Hardness Durometer and the PosiTector BHI Barcol Hardness Gauge use a precisely formed tip or indenter connected to a calibrated spring and measure how far the tip penetrates the material. The greater the penetration depth, the softer the material.

What is shore hardness?

Over 100 years ago, Albert Ferdinand Shore invented the Shore durometer, which offered different scales for measuring the hardness of various materials such as thermoplastic elastomers, vulcanized (thermosetting) rubbers, elastomers, soft gels, and hard plastics.

Shore hardness testing is a quick way to determine how a material behaves against impact and abrasion.

Shore D hardness gauges are also commonly used to determine if a coating is sufficiently cured.

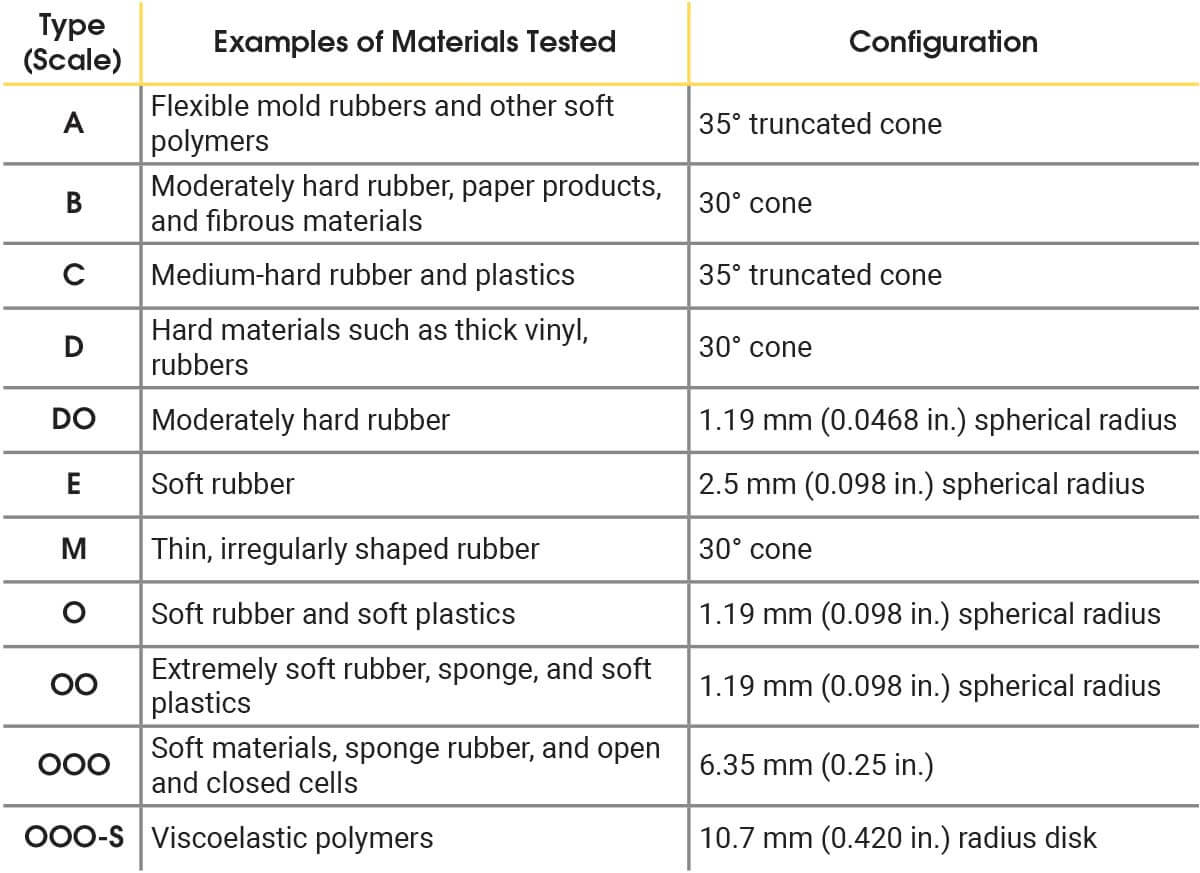

ASTM D2240-Standard Test Method for Rubber Property-Durometer Hardness distinguishes twelve different durometer scales: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO- S and R

The different scales apply to materials with different properties.

What is a Shore Hardness Durometer?

Shore hardness is best measured with a handheld electronic meter such as the PosiTector SHD. A simple, easy-to-read digital display takes the guesswork out of old analog scales. The device has internal storage and free desktop software that facilitates reporting. HiLo alerts, statistics mode and auto-ignore mode make quality control easier than ever.

How is shore hardness measured?

The PosiTector SHD Digital Shore Hardness Tester is a hand-held hardness tester designed to minimize the risk of operator error. This guide is written for the PosiTector SHD but can be used with any manual shore hardness tester.

Step 1: Determine a test site

The Shore Hardness Tester should be used on a hard, solid surface. If the material is thin or otherwise likely to deform, it should be placed on a firm surface for the duration of the test.

The measuring points should be at least 6 mm (0.24") apart.

Step 2: Take a measurement

Press the probe firmly onto the material to be measured until the foot of the indenter is in full, flat contact with the surface and hold firmly. The test timer starts counting down. When the timer reaches 0 seconds, the meter will beep twice and display the reading.

Checking the Accuracy of a Shore Hardness Durometer

Before and after each work shift, check the accuracy of the durometer using the included check blocks. Place the check block on a hard, flat surface. To get the most accurate Shore hardness reading, press firmly on each test block with the APosiTector SHD or DPosiTector SHD and take 3-5 readings, measuring points at least 6mm apart.

What are the benefits of using a PosiTector SHD A or PosiTector SHD D Digital Shore Hardness Durometer / Hardness Tester?

LCD display

The easy-to-read digital display takes the guesswork out of reading analogue scales and reduces the risk of operator error.

Memory, statistics and USB port

The PosiTector SHD has internal memory for recording data. The on-screen statistics mode is continuously displayed/updated during Shore hardness measurement. Once the measurement is complete, the stored readings and graphs can be downloaded to a PC or Mac via the built-in USB port.

Free software solutions

To log and store shore hardness readings, DeFelsko offers free solutions for viewing and analyzing readings. With DeFelsko's PosiSoft solutions, you have a choice of our desktop version, an easy-to-use mobile app for iOS and Android, or PosiSoft USB - a simple gauge interface that resembles a USB stick.

Test Timer

When measuring the hardness of a material, the PosiTector SHD shows a timer on the screen. The timer will start counting down automatically as soon as the indenter is pressed down firmly. When the time (usually 3 seconds) has expired, a measurement is taken.

Continuous readings

Continuous reading mode is ideal when a test timer is not required or when a calibration check is to be performed. When enabled, the PosiTector SHD will continuously display Shore Hardness readings.

Statistics mode

Readings and statistics can be recorded in memory for further analysis and reporting. The average, standard deviation and min/max hardness statistics are continuously updated and displayed as you measure with the device. PosiTector SHD.

HiLo-Alarm

The HiLo alarm on the PosiTector SHD allows the meter to audibly and visually alert the user when readings exceed user-set limits.

Auto Sub-Batch

With the PosiTector SHD probe in conjunction with a PosiTector Advanced base unit, Auto-Sub-Batch automatically creates a new sub-block after storing the required number of readings.

Which test standards are there for measuring shore hardness?

The following standards are used to determine the shore hardness of a material:

ASTM D2240 Standard Test Method for Rubber Property-Durometer Hardness

ASTM D2240 guides the user through measuring the hardness of flex rubber. It defines suitable techniques and procedures for measuring soft rubber and lists twelve types of measurement.

"1.1 This test method applies to twelve types of rubber hardness testers known as durometers: Types A, B, C, D, DO, E, M, O, OO, OOO, OOO-S and R. The method for Determining the indentation hardness..."

"4.1 This test method is based on the penetration of a specific type of indenter pressed into the material under specified conditions.

ASTM D2240 test method using the PosiTector SHD

- Place the workpiece on a flat, hard, horizontal surface to ensure positioning and stability. Place the indenter on the specimen with enough pressure to ensure firm contact. Press down in a firm, steady motion to avoid slipping or scraping that could give an incorrect reading and damage the probe tip.

ISO 48-4:2018 Rubber, vulcanized or thermoplastic - Determination of hardness - Part 4: Indentation hardness by the durometer method (Shore hardness)

"This first edition of ISO 48-4 cancels and replaces ISO 7619-1:2010, which has been technically revised."

According to ISO 48-4, the measurement of a rubber's hardness with a durometer (Shore hardness) is based on the rubber's response to an applied indentation. The reaction varies and depends on many factors.

See ISO 48-4:2018 for a full description.