Summary: The coating performance is related to the profile height on the steel surface. Three types of devices or methods are available for measuring this surface profile: replica film impression tape, depth micrometer and probe roughness tester. This paper presents the results of a recent analysis of measurements made with the three types of equipment on steel blasted with different abrasives. In addition, a new method of measuring with depth micrometers, called the mean of the maximum peak values, is proposed.

Surface profile - a detailed comparison of measurement methods

Products mentioned: PosiTector SPG, PosiTector RTR H

Summary: The coating performance is related to the profile height on the steel surface. Three types of devices or methods are available for measuring this surface profile: replica film impression tape, depth micrometer with pointed measuring sensors and stylus roughness tester. This paper presents the results of a recent analysis of measurements made with the three types of equipment on steel blasted with different abrasives, and proposes a new method of measuring with depth micrometers, called the mean of the maximum peak values. more detailed

Introduction to surface profile measurement

Steel surfaces are often cleaned by abrasion prior to the application of protective coatings. This process removes previous coatings and roughens the surface to improve coating adhesion. The resulting surface profile, or anchor pattern, consists of a complex pattern of peaks and valleys that must be accurately evaluated to ensure compliance with job or contract specifications.

Several test methods are available to protective coatings professionals to determine the extent of the surface profile. So far, there is little information that could help them choose an instrument or compare the results of different methods.

Measurement methods - How is the surface profile measured?

A steel surface after blasting consists of random irregularities with peaks and valleys that are not easy to characterize. Instruments that can measure this profile with a high degree of precision, such as B. scanning electron microscopes are only suitable for use in the laboratory. Field methods are desirable. Surface profile ranges are often given and the recommended surface profile will vary for different types of coatings.

The determination of the surface profile depends on its definition. ISO1 8503-12 defines it as the height of the largest peaks relative to the largest valleys. ASTM3 D71274 describes it as the positive and negative vertical deviations from a centerline that is approximately at the center of the profile being evaluated. ASTM D4417-115 defines surface profile as "the elevation of major peaks relative to major valleys".

Surface profile - a detailed comparison of measurement methods

Three different measurement methods are described:

- Method A - Profile ComparisonMethod B - Depth MicrometerMethod C - Replicafilm Impression Tape

Figure 1 ASTM surface profile measurement method

In the industry there are no profile standards with values that can be traced back to a national metrology institute. If this were the case, devices could be checked against these standards, accuracy claims could be published, and users could compare their results. With the help of standards, the relationship between the values of impression bands and the values of depth microns, etc. could be determined.

Since there are no physical standards, the industry has opted for a reference method. NACE, ASTM and ISO describe the height of the surface profile as the distance between the highest peak and the lowest valley in the field of view of an optical microscope. A microscope is focused on the highest peak in the field of view. The distance the lens travels to focus on the deepest valley within the same field of view is a single profile height measurement. The arithmetic mean of 20 such measurements gives the mean maximum height from peak to valley. In other words: the average of the maximum peak values.

Figure 2 Computer generated image of a blasted steel surface (left) and a blasted surface (right)

As the microscope method is not practical on site, the major organizations support a number of alternative methods which are both practical and routinely used by inspectors.

ISO manufactures surface profile comparators for blasted steel based on the focusing microscope method. The user compares the steel surface, by visual or tactile means, to the profile of each segment of the comparator to give an appropriate grading of "fine", "medium" or "coarse". Annex B of ISO 8503-5: Impression method for determining roughness (ISO 8503-5:2017) shows that there is a good correlation between these comparators and the impression tape and stylus measurement. There is no ISO method for depth micrometers, nor should depth micrometers be used to measure on profile comparators as they are not flat.

The NACE RP0287 standard (2016 updated to SP0287-2016-SG) also shows that the impression tape and focusing microscope measurements agree within their limits (two standard deviations) in 11 out of 14 cases.

How Replica Film Gauges (Depth Micrometers) Measure Surface Profile

The use of replica film or impression tape is simple, inexpensive and shows a good correlation to the results of the focusing microscope. It is therefore not surprising that this has become the most popular method for measuring surface profiles.

The replica film or impression tape consists of a layer of compressible foam applied to a non-compressible polyester support of very uniform thickness (50.8 µm 5.08 µm).

When the foam is pressed against a roughened steel surface, it collapses and forms an imprint of the surface. Placing the compressed ribbon between the anvils of a depth micrometer and subtracting the contribution of the incompressible substrate 50.8 μm gives a measure of the surface profile.

With the PosiTector RTR H, the 50.8 μm non-compressible film is automatically subtracted from all readings.

Figure 3 Replica film / print tape

According to ISO 8503-5, "This method measures an 'average maximum peak-valley profile' because the depth micrometer anvils flatten the impression profile slightly so that the reading corresponds to an average maximum value, although this is not the same as a mathematical average." This is a method that essentially measures the average of the maximum peak values.

In recent years, two other methods of profile measurement have gained popularity: the stylus (ASTM D7127) and the depth micrometer (ASTM D4417 Method B). Electronic versions of these devices have the advantage that the operator has less influence and the measurement data is recorded and analyzed digitally.

For more information on our digital surface profile gauges, see DeFelsko PosiTector SPG surface profile probes or DeFelsko PosiTector RTR-H roughness gauge

How stylus roughness gauges measure surface profile

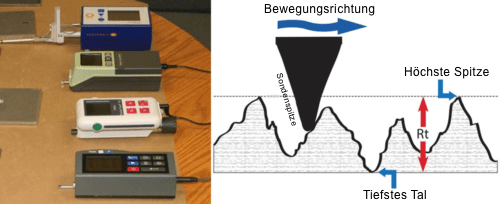

In a hand-held surface roughness measurement device, a stylus is drawn across the surface at a constant speed. The device records the up and down distances traveled by the pen as it traverses the surface. It measures Rt in accordance with ISO 428710, where Rt is the vertical distance between the highest peak and the lowest valley within a specified evaluation length of 1.27 cm (0.5"). Five of these measurement curves are created and the Rt values averaged to again obtain the mean of the maximum peak values.

Figure 4 Stylus roughness gauges (gauges shown are similar to those used in this study)

Figure 5 ASTM Comparison Chart

How depth micrometers measure surface profile and how they compare to replica film gauges and stylus roughness gauges

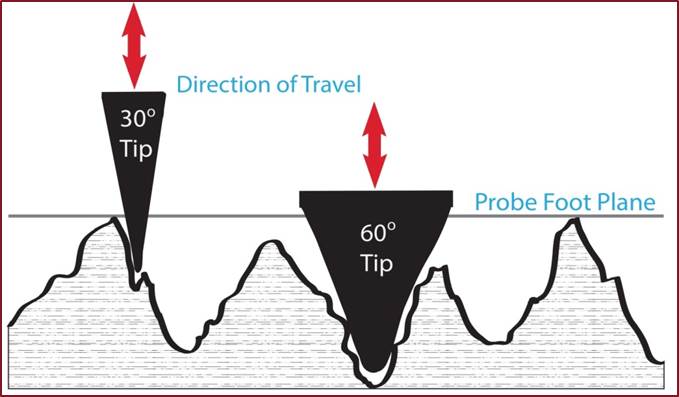

A depth micrometer has a flat probe tip that rests on the surface to be measured and a spring-loaded probe tip that protrudes into the indentations of the surface profile. The flat base rests on the highest peaks, so each measurement corresponds to the distance between the highest local peaks and the particular valley into which the peak has penetrated.

Figure 6: Depth micrometer overview

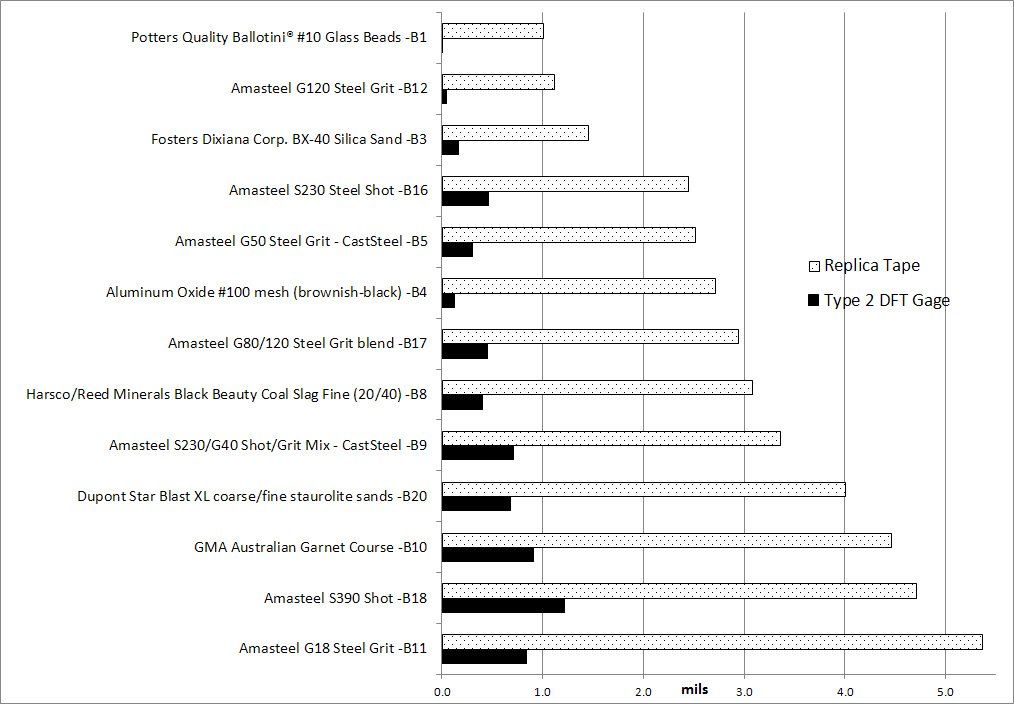

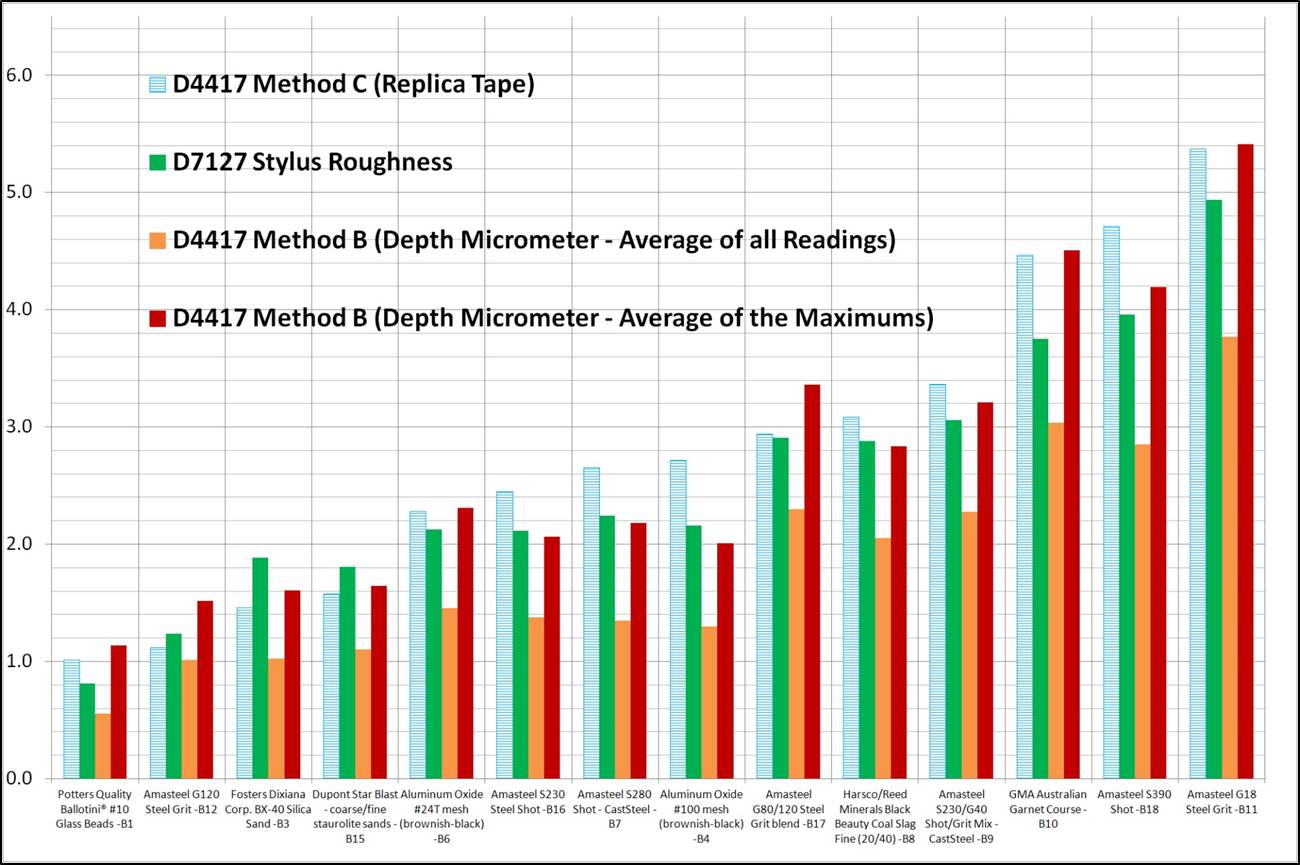

Currently, the ASTM D4417 standard requires the user to average all depth micrometer measurements, regardless of how low some readings are. Not surprisingly, the final calculated results are usually lower than those obtained with the tape and stylus methods. This study confirmed this assumption (Fig. 12). Occasionally one of the devices recorded readings that matched or exceeded the tape measure readings, but that was the exception.

According to the ASTM 5 panel study mentioned above, the depth micrometer method was the only method without a comparative study. In order to allow correlation between all three types of equipment, this paper proposes that depth micrometer measurements be analyzed using a method that produces results similar to those obtained from tape and styli and consistent with their measurement objectives, a method called "Maximum Peak Average". .

To obtain this value, the profile is measured at a sufficient number of locations to characterize the surface, typically five. Ten measurements are taken at each location and the highest value is recorded. The average (mean) of all measurement points is given as the profile of the surface.

The impetus for this study came from preliminary tests on ASTM plates with a single depth micrometer. As can be seen in Figure 5, using the average of the maximum peaks, the depth micrometer results were consistent with the tape and stylus results.

Summary of tests comparing depth micrometers to Replicafilm gauges and stylus roughness gauges

To verify these results, twenty commonly used media blasted plates were obtained from KTA Labs11 and five commonly used depth micrometers were purchased.

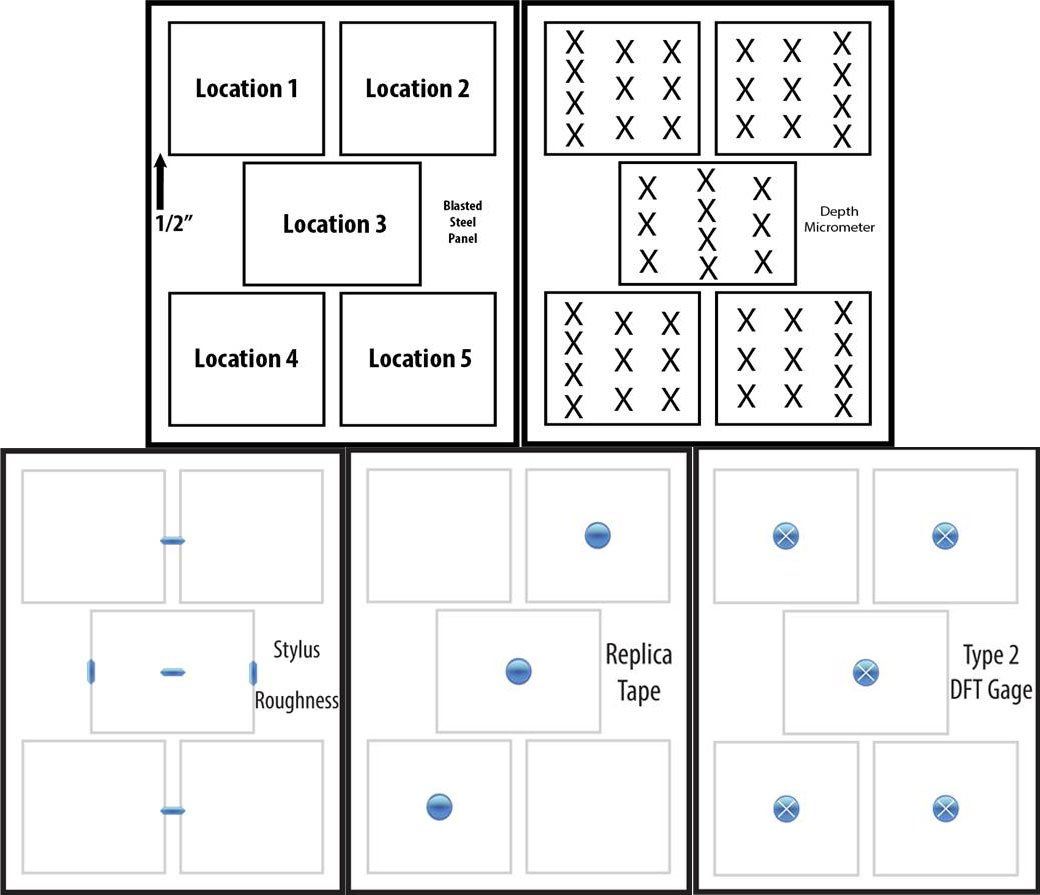

Five people took 50 readings on each panel using each device in a controlled work environment, for a total of 5,000 readings.

At least 3 replica film measurements were carried out on each plate. If the results fell within the outer limits of the measurement range, additional measurements were taken with the next higher replica film and the average was determined according to the manufacturer's instructions.

For comparison, roughness measurements were carried out with three common measuring devices. Finally, the base metal readings (BMR) of each panel were determined using magnetic coating thickness gauges.

Figure 7, measuring points for the individual methods

Effect of surface profile on coating thickness gauges

Coating thickness probes measure the distance between their probe tip and the magnetic plane in the steel. With smooth steel, the magnetic plane coincides with the surface of the steel. For rough steel, the magnetic plane lies somewhere between the highest peak and the lowest valley of the profile, a position that can vary depending on the device type. Therefore, roughness generally causes coating thickness gauges to read a high or positive reading.

SSPC-PA 2 and other standards require the application of a correction factor to compensate for this roughness effect. A plastic pad is usually placed over the bare profile and measured with the coating thickness gauge. The gauge is adjusted so that the result matches the thickness of the washer. The underlay simulates the paint build-up over the peaks and the adjustment ensures that the paint thickness measurements are taken from the average peak height of the profile and not from the magnetic plane

To quantify the effect of profile on coating thickness gauges, Type 1 (mechanical deduction) and Type 2 (electronic) gauge measurements were taken on all panels, having previously been zero-tested on smooth, flat steel. The average result of five measurements was recorded for each panel.

The Type 1 device was the least affected by the profile, measuring a maximum of 0.3 mils on the roughest surface. The Type 2 device measured between a low of 0 on the bead blasted surface and a high of 1.2 mils on the S390 shot blasted surface. Overall, the thickness gauge provided thickness results that ranged from 1 to 26% of the surface profile heights measured with the impression tape, with an average of 13% for all panels.

Figure 8, Coating Thickness Gauges versus Replica Film Gauges

General observations on surface profile measurement

Some surface roughnesses are beyond the capability of replica film gauges and stylus roughness gauges. In practice, it is assumed that commercially available adhesive tape qualities enable the measurement of average roughness profiles between 12.7 and 127 µm. All of the depth micrometers used in the study had an extended measurement range suitable for measuring blasted steel surfaces and did not reach their "maximum" on any panel.

The measuring ranges can be found on the respective product pages for the PosiTector SPG surface profile measuring devices.

There were areas on several panels where all instrument types gave high profile values. These discrepancies could be due to the irregularities of hand blasting. It can be assumed that larger areas would show similar irregularities.

It was not possible to test each device in the exact same location on each panel (Figure 7). The impression tape (replica film) examines a relatively large area, so fewer measurements were required to adequately characterize the surface. Stylus and depth micrometer methods have fine-tipped probes that scan a much smaller surface area and therefore require more measurements to adequately characterize a surface.

This is taken into account in the ISO, ASTM, NACE and SSPC guidelines.

All methods required initial setup and accuracy verification before testing began.

Read the PosiTector SPG and PosiTector RTR H user guides for setup and accuracy verification information.

The replicafilm method required checking the accuracy of the micrometer against a known thickness (such as a plastic backing) and setting the scale back 2 mils to account for the incompressible layer of plastic. Minor adjustments had to be made during testing to compensate for micrometer drift.

The stylus roughness measuring devices required the most adjustment work. The correct gage length was entered, reporting parameters such as Rpc (peak count) and Rt (maximum peak-to-valley height in a gage length) were set, and the tool had to be carefully positioned on the blasted steel surface.

The depth micrometers were zero checked before and after each set of 50 measurements on a glass plate and backing plate of known thickness. During the entire test, no instrument deviated from the zero point.

- The replicafilm method required checking the accuracy of the micrometer against a known thickness (such as a plastic backing) and setting the scale back 50.8 µm to account for the incompressible layer of plastic. Minor adjustments had to be made during testing to compensate for micrometer drift.

- Most of the adjustments were required on the stylus roughness gauges. The correct evaluation length was entered, reporting parameters such as Rpc (peak count) and Rt (maximum peak-to-valley height in an evaluation length) were set, and care had to be taken to position the device on the blasted steel surface.

- The depth micrometers were zero checked before and after each set of 50 measurements on a glass plate and backing plate of known thickness. During the entire test, no instrument deviated from the zero point.

Circles were observed on some panels after testing with replica film impression tape. They were probably caused by microscopic particles that had become embedded in the foam and were carried away when the foam was pulled off. Scratches were found on some panels after testing with the stylus gauge. It is believed that the steel surface was slightly damaged when the diamond stud was drawn across the tips (Fig. 9).

Figure 9 A 400x magnified photograph of garnet blasted steel with a scratch

During the tests, it becomes clear that the results of individual surface profile measurements are less repeatable and show greater fluctuations than users are used to from other industrial measurement methods such as dry film thickness, temperature or gloss testing. While two dry film thickness measurements can be expected to be very close, two surface profile measurements can differ significantly. This is in the nature of a blasted surface.

A panel blasted with a mixture of coarse and fine staurolite sand measured between 45.72 and 73.66 µm with the replica film, between 45.72 and 71.12 µm with the stylus roughness tester and with the depth micrometer between 0 and 142.24 µm. Nevertheless, all three methods gave an "average of maximum peaks" of about 63.5 µm.

Just as often, however, the three methods also provided results that were not so close to each other. The results of the replica film and the stylus roughness tester sometimes differed by up to 30%. For two panels blasted with S280 abrasive and 100 grit aluminum oxide, the replica film read 68.58 µm while the stylus method averaged 55.88 µm. In contrast, for BX-40 silica sand, the replica film impression tape read 38.1 µm, while the stylus roughness tester returned a higher average of 48.26 µm. The average values for the three stylus roughness testers were higher than the replica film impression tape values for all 4 grit blasted panels and lower for all oxide and shot blasted panels. See Figure 12 for a summary of replica film impression tape and stylus roughness tester results.

Observations on the measurement with the depth micrometer

When measuring the surface profile with the depth micrometers, the following points were noted:

- Loose Surface Contaminants: Several panels yielded high outlier measurements that were not considered in the final analysis. Participants reported that the instruments "rocked" on the surface. This alerted them to the problem of surface contamination, so they avoided these areas Measurement bias: Sandblasted panels had less bias than glass bead blasted panels. From 250 readings taken with one device on a garnet blasted 4"x6"x1/8" panel, the results ranged from 0.2 to 1.9 mils. If only the highest readings were averaged, the result was flat of 1.2 mils, close to the tape and stylus results. Occasional low readings near zero were obtained. They were probably caused by a large spike pushing the probe tip near the level of the instrument base. By averaging only the maximum readings prevents these low readings from affecting the bottom line.The highest reading in the above example of 1.9 mils is also of interest.It seems to indicate a single, deep valley into which the probe tip dipped, a large peak in the profile that lifted the foot of the depth micrometer, or a surface waviness, however, it was just one result of many that were averaged to produce a meaningful profile measurement to receive a message.

- Number of Measurements for Analysis: When only 3 measurements were taken at each location on the plates, the results did not agree exactly with the results from the gages, suggesting an insufficient number of measurements. With 5 measurements per spot, the final results were closer to the gage results. Increasing the number of measurements to 10 per point (according to ASTM) eliminated the apparent randomness of the results and provided the best correlation with the results from the gage and stylus methods. More measurements hardly improved the results. Reducing the number of measurement points from 5 to 3 had little impact on the overall results. This indicates that a minimum of 10 readings at each of the 3 locations adequately characterizes a blasted profile surface.

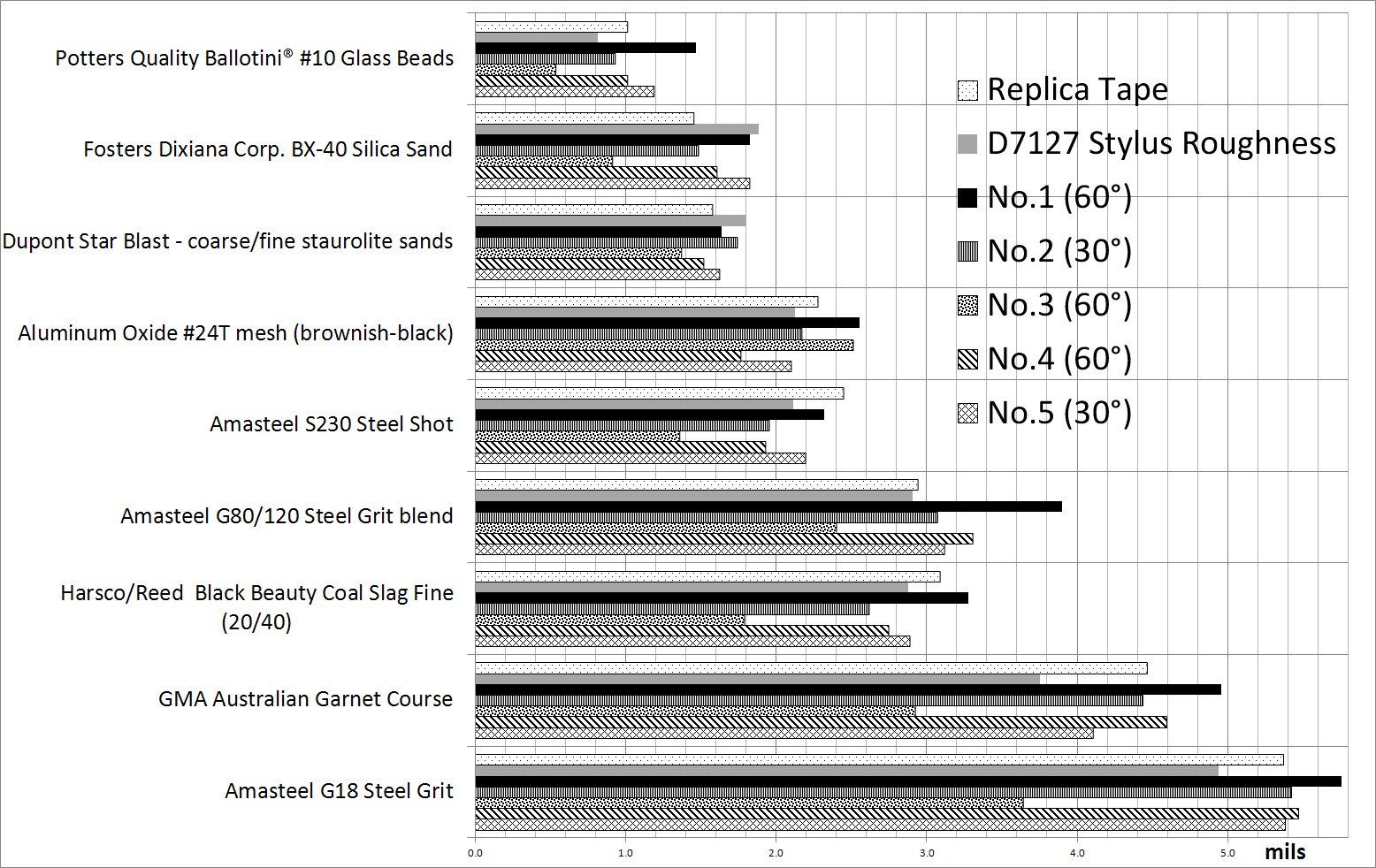

- Different results with the depth micrometers: The depth micrometers used in this study had probe tips machined at an angle of 30° and 60°. Their spring pressures ranged from 70 to 125 g of force. Devices with 30° probes often gave lower results than devices with 60° probes. Instruments with weak tactile forces generally gave lower results than instruments with strong tactile forces. This suggests that the angle of the probe tip and the force of the probe tip affect the measurement results (Fig. 10). High-resolution photos of the probe tips were examined. All of the tips correctly measured 30 or 60° as advertised, but their tip radii varied significantly. Some were really rounded. Others featured flattened or chiseled ends (Fig. 11).

Fig.10 Results from all depth micrometers

Fig.11a High resolution photo of different depth micrometer tips

Fig.11b Close-ups of different depth micrometer tips

- Analysis Methods: When 50 readings of each depth micrometer were averaged according to ASTM D4417, the resulting profile height measurements were almost always lower than those of the replica film/imprint tape and the stylus roughness meter. When only the maximum values from each site were averaged, the results correlated better with those of the replica film/impression tape and the stylus roughness tester (Fig. 12).

Fig.12 Comparison of measurement methods, results from devices of one type are summarized

Conclusions and Deductions

The results of this study confirm the close relationship between tape measure and stylus measurements as previously established in the ASTM interlaboratory comparison. The results also revealed interesting information about the third type of gauge, the surface profile depth micrometer, which yielded comparable results to the tape measure and caliper when using the 'maximum peak average' analysis approach (Fig.12).

The surface of the blasted steel undergoes a random change at each point, so a series of measurements must be taken. The goal of the evaluation is to make a maximum of peak-to-valley determinations. Individual surface measurements of a blasted metal surface will vary significantly from area to area in a given area. How these measurements are combined depends on the parameter required for the task, which can be the average peak-to-valley height, its maximum, or something else. By applying the "maximum peak average" analysis approach, a depth micrometer provides reliable surface profile measurements that correlate closely with replica tape and stylus instrument results.

PosiTector SPG Advanced models feature SmartBatch mode to meet various standards and testing methods. By default, SmartBatch produces results that approximate those of the replica tape and drag pin method by automatically averaging the maximum tread depth for all points within the test area and displaying "the average of the maximum peaks".

Sources:

- International Organization for Standardization (ISO), 1 rue de Varembé, Case postale 56, CH-1211, Geneva 20, Switzerland Preparation of steel substrates prior to the application of paints and related products - Surface roughness characteristics of blast-cleaned steel substrates - Part 1: Specifications and definitions for ISO Surface Profile Comparators for Evaluating Blasted SurfacesASTM International, 100 Barr Harbor Drive, West Conshohocken, PA 19428ASTM D7127 "Standard Test Method for Measurement of Surface Roughness of Abrasive Stray Cleaned Metal Surfaces Using an Electronic Portable Stylus Instrument" (West Conshohocken, PA: ASTM)ASTM D4417 "Standard Test Methods for Field Measurement of Surface Profile of Blasted Cleaned Steel" (West Conshohocken, PA: ASTM) From NACE Standard RP0287-2002, "Field Measurement of Surface Profile of Abrasive Stray-Cleaned Steel Surfaces Using a Replica Tape". (Houston, TX: NACE, 2002)ISO 8503-2 Preparation of steel substrates prior to the application of paints and related products - Surface roughness characteristics of blasted steel substrates - Part 2: Method for classifying the surface profile of blasted steel - Comparative methodsResults of NACE Working Group T interlaboratory tests -6G-19. Report of the Technical Committee of NACE 6G176 (withdrawn). "Cleanliness and Anchorage Patterns by Wheel Blasting of New Steel" (Houston, TX: NACE International). (Available from NACE International as a historical document only.) This statistical summary was performed using imperial units. For conversion to metric units, 1 mil = 25.4 microns (μm) is used. ISO 4287: 1997 Geometrical Product Specifications (GPS) - Surface texture: profile method - Terms, definitions and surface parameters KTA-Tator, Inc. (KTA), 115 Technology Drive , Pittsburgh, PA 15275 USA.