Measurement of the cure index with the oven temperature logger PosiTest OTL

Improved quality control of powder coatings with PosiTest OTL oven temperature logger using cure index

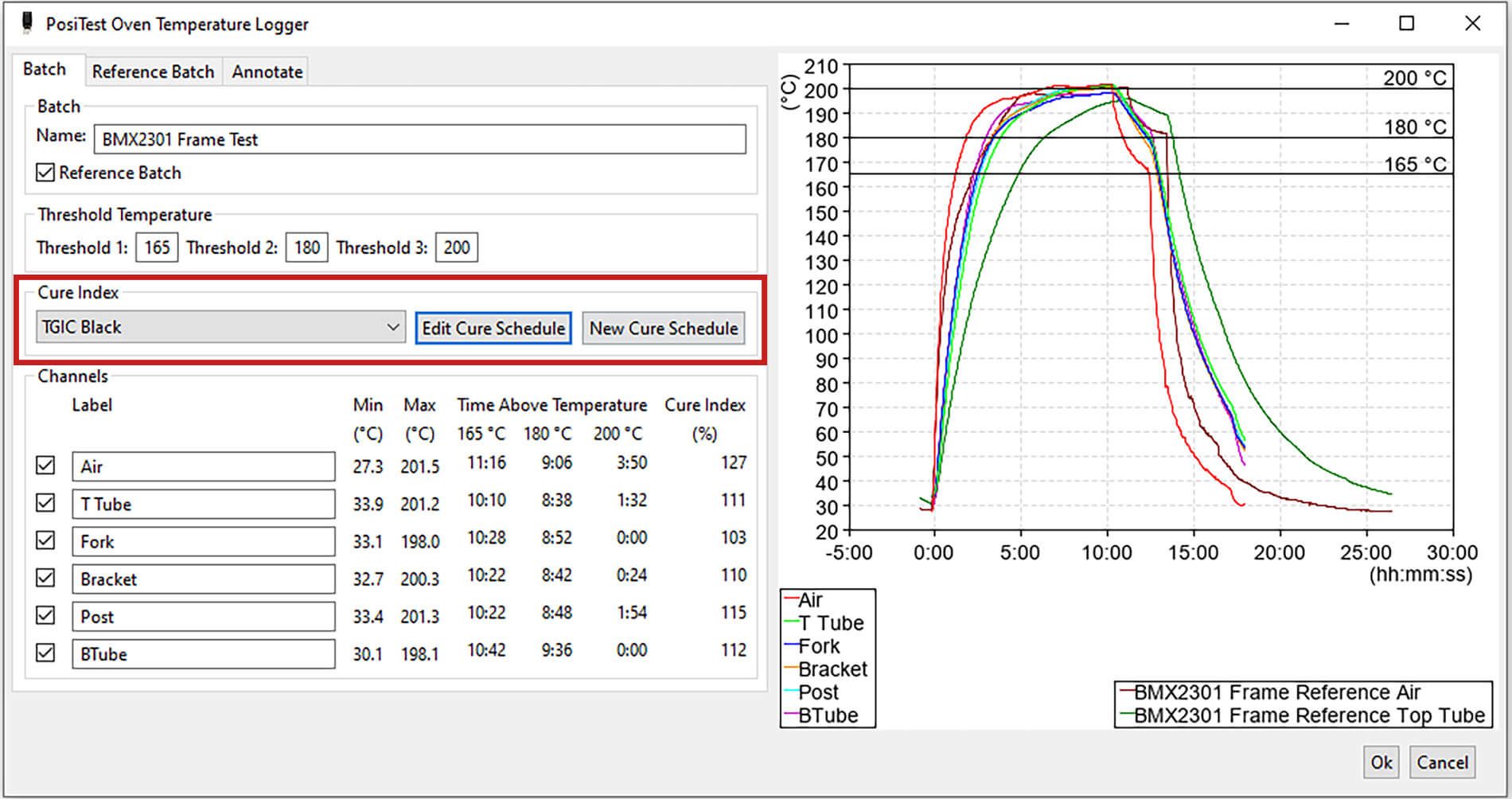

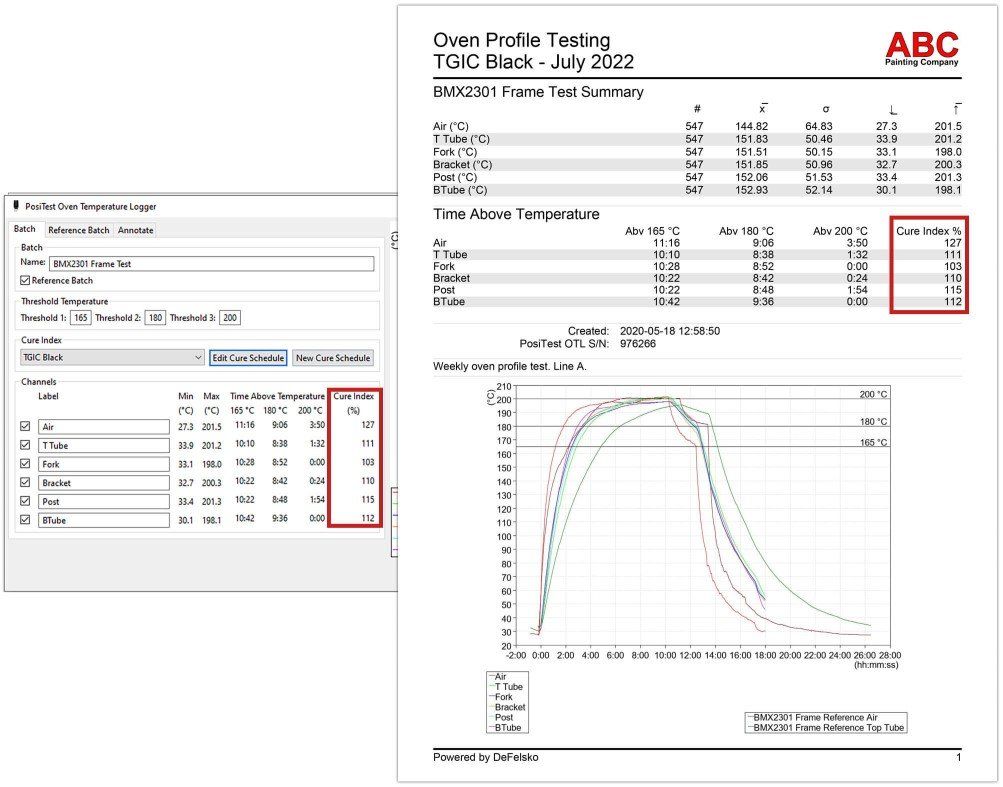

PosiSoft Desktop Software can now calculate the Cure Index from readings from the PosiTest OTL oven temperature logger.

The Cure Index allows the user to quickly determine if each measurement point has had sufficient time at temperature x to ensure complete curing of the coating.

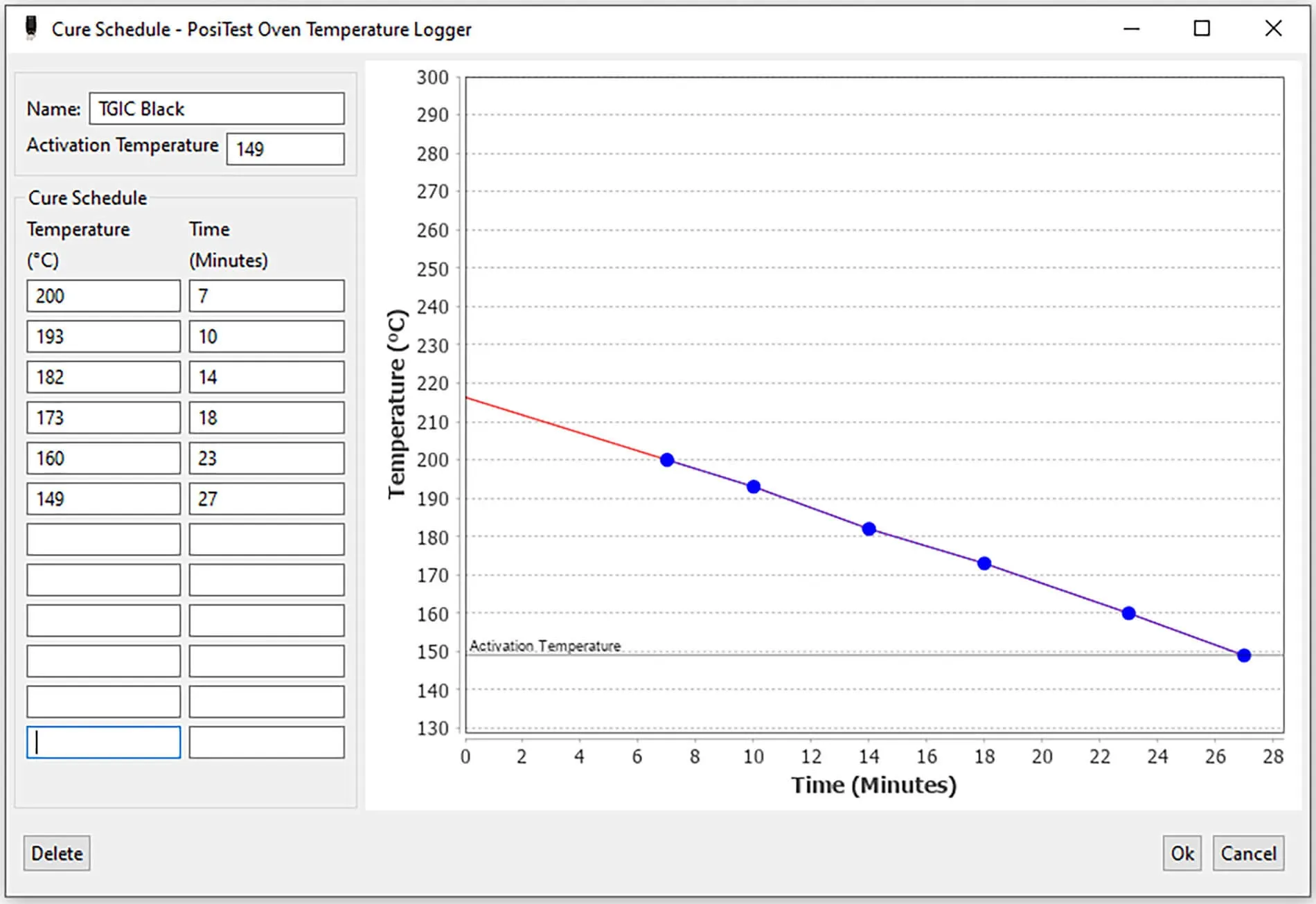

For proper curing of a powder coating, most powder coating manufacturers specify minimum substrate time(s) and temperature(s) that will ensure proper curing. For example, a common powder coating manufacturer specifies the following "curing schedule" for one of their polyester TGIC powder coatings:

- 7 minutes at 200°C (392°F) 10 minutes at 193°C (379°F) 14 minutes at 182°C (360°F) 18 minutes at 173°C (343°F) 23 minutes at 160°C (320°F)27 minutes at 149°C (300°F)

It is important to note that the temperatures quoted are the substrate (workpiece) temperature and not the air temperature. In practice, it is impossible to immediately heat the substrate to a certain temperature, hold it at that temperature, and then immediately cool the part back to room temperature.

Instead, most part temperatures follow a "bell shaped" curve. Just measuring the time that the part is above a certain temperature can misrepresent the cure:

- As the part heats and cools, it spends time above the activation temperature (minimum temperature for curing) but below the target temperature. During transit through the oven, the part often remains above the target temperature

In addition to measuring elapsed time at a given temperature, it makes sense to consider the curing that occurs when the part is above or below the target temperature.

How to set up a cure schedule for PosiTest OTL in PosiSoft Desktop?

The PosiTest OTL Oven Temperature Logger, in combination with PosiSoft Desktop Software, calculates a cure index specifically designed for the powder coatings industry. With a single number, the Cure Index makes it easy to determine if a powder coating has adequately cured according to the manufacturer's curing schedule. The slow (but reasonable) cure at temperatures between the activation (minimum cure) temperature and the target temperature is accounted for, as is the accelerated cure that occurs when the part is above the target temperature. The result is a percentage cure index: a cure index greater than 100% means the coating is fully cured, while a cure index less than 100% indicates the coating may not have fully cured and therefore not attained the stated material properties. In general, most fabricators set oven conditions to maintain a "safety margin" above 100% cure to ensure that the cure is not affected by everyday variations.

To measure cure index, simply connect the temperature probes to the PosiTest OTL oven temperature logger and the desired locations on the uncoated part to be measured. Turn on the PosiTest OTL and press the record button to begin recording. Place the logger in the heat protection box and send it through the oven. As the logger and part pass through the oven, the temperature is measured at up to six locations at two-second intervals. Once the measurement is complete, connect the logger to a PC or Mac via USB and import the measurement data into the included PosiSoft Desktop software. For simplification and organization, the logged measurement data is imported into a separate block (group).

Double-click the newly imported block to open the PosiSoft OTL Block Editor. Then select a previously entered Curing Schedule or select 'New Curing Schedule' to create a new one.

In the Curing Schedule Editor, enter the powder manufacturer's recommended specifications for the curing schedule or curing curve. In addition to the activation temperature, time/temperature pairs (up to 12 pairs) can be entered. The activation temperature (minimum temperature for curing) is the minimum temperature specified by the manufacturer at which curing should begin. If no activation temperature is added, the lowest time/temperature specification is assumed as the activation temperature.

Once the curing plan has been created, a cure index is displayed in the PosiSoft OTL Batch Editor and in all reports, giving an instant, at-a-glance view of whether a full cure has been achieved at each measurement location.

For more information about the PosiTest OTL oven temperature logger, please read the article PosiTest OTL oven temperature logger for optimal process control

There are also two high-quality oven temperature logger sets from Grant in Cambridge, UK:

- Grant OMK 610 Oven Temperature Data Logger Kit Standard

- Grant OMK 610 Oven Temperature Data Logger Kit Advanced with increased heat protection performance

Business hours:

Monday - Thursday from 8:30 a.m. to 5 p.m. and Friday until 3 p.m