News about mtv messtechnik products

New product or update released?

Find out about all the news here!

We mourn the loss of our founder and managing director

Johannes R. Vogel

He passed away unexpectedly at the age of 58.

His entire life and work was filled with great energy and drive for the benefit of the company and all its employees.

For more than three decades, he successfully shaped our daily work with his vision, his sense of opportunity and his own high level of commitment.

In him, we have lost an extraordinary personality who shaped us with all his warmth and humanity.

We are deeply saddened by his passing. We will always remember Johannes with gratitude as a boss, businessman and friend, and we will keep him close to our hearts.

We will miss you!

In silent remembrance

The team of mtv messtechnik oHG

mo Magazin für Oberflächentechnik

New Dew Point Logger PosiTector DPM L+ from DeFelsko premiers at the European Coatings Show 2025!

The new PosiTector DPM L+ dew point logger from DeFelsko works independently, unlike other measuring probes in the PosiTector series, which are usually coupled with a base unit. Its main field of application is in the area of heavy-duty corrosion protection. Attached to steel structures with a magnet, the device measures the environmental parameters relevant to the coating and records them autonomously over a period of up to 600 days. The data can be transferred wirelessly from the measuring instrument to a PC, Mac or tablet computer via Bluetooth or Wifi.

...read the full PDF

here

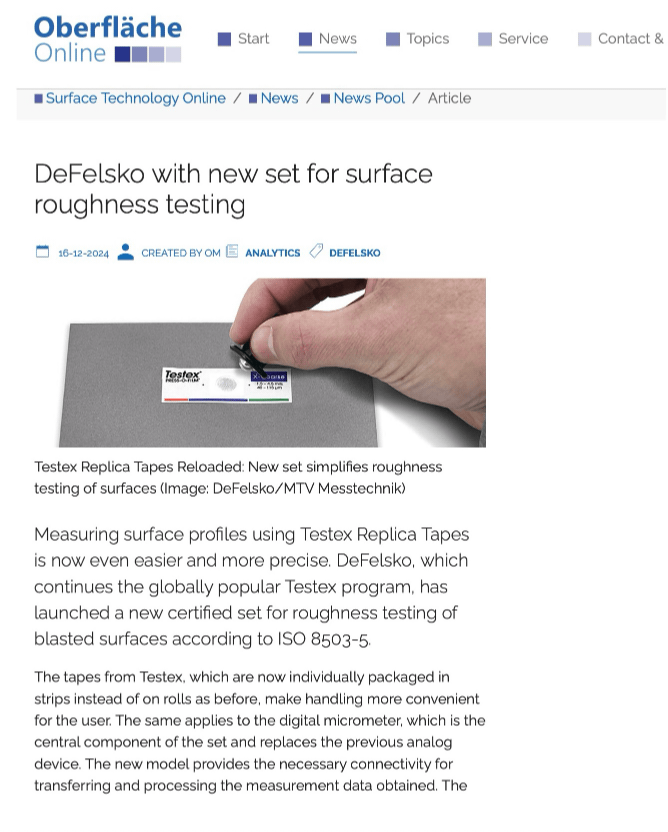

Interesting article on Oberfläche online about DeFelskos & mtv messtechnik´s new certified set for roughness testing of blasted surfaces according to ISO 8503-5.

Measuring surface profile using Testex Replica Tape

got even easier and more precise. DeFelsko and mtv messtechnik have launched a certified set for roughness testing of blasted surfaces according to ISO 8503-5.

HAPPY

30th BIRTHDAY!

🎉

mtv messtechnik celebrates 30 successful years!

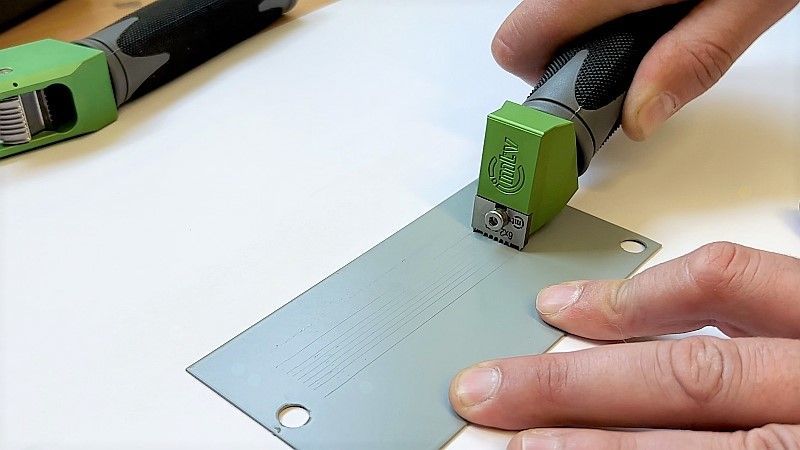

New article in the German magazine for surface technology

Oberfläche online

about the mtv messtechnik CC 1000 and CC 3000 series of Cross Cut Testers

New article in

mo, magazin für Oberflächentechnik

from Germany:

mtv messtechnik simplifies adhesion testing of coatings

The automatic reset of the movable cutting head facilitates the execution of the grid cut for testing the adhesion of coatings. The adhesion testers are for cut distances between 0 and -250 µm.

Cross cut with MTV CC 1000 to determine the adhesive strength and elasticity of a surface.

For curved surfaces, mtv messtechnik offers testers with flexible, individually mounted blades

(Image: mtv)

mtv messtechnik has trimmed both the CC 1000 and CC 3000 series for ergonomics and easy handling. Thus, all of the company's cross-cut testers are equipped with an automatic reset. The practical carrying case in which they are delivered contains, in addition to the respective device, an illuminated magnifying glass, medium-hard brush depending on the model version, and an Allen key. The latter is used to change the cutting tool. It is recommended to replace the cutting edge after 200 to 500 grid cuts - depending on the hardness of the substrate.

Cross-cutting according to DIN EN ISO 2409 and ASTM D 3359 can be used to test the adhesion of coatings and painted surfaces up to a maximum layer thickness of 250 µm. To do this, the materials tester makes six parallel scribe cuts and six additional "cross cuts" at right angles on the coating to be evaluated. Depending on the coating thickness, the spacing of the individual cuts can be one to three millimeters. In this way, a uniform pattern - a grid - of 25 squares is created. After the cross-cut has been made, loose particles are removed and the result is evaluated. A distinction is made between cross-cut characteristic values from 0 (very good) to 5 (very poor), abbreviated Gt 0 to Gt 5.

Click here to read the PDF of the article or click on the image

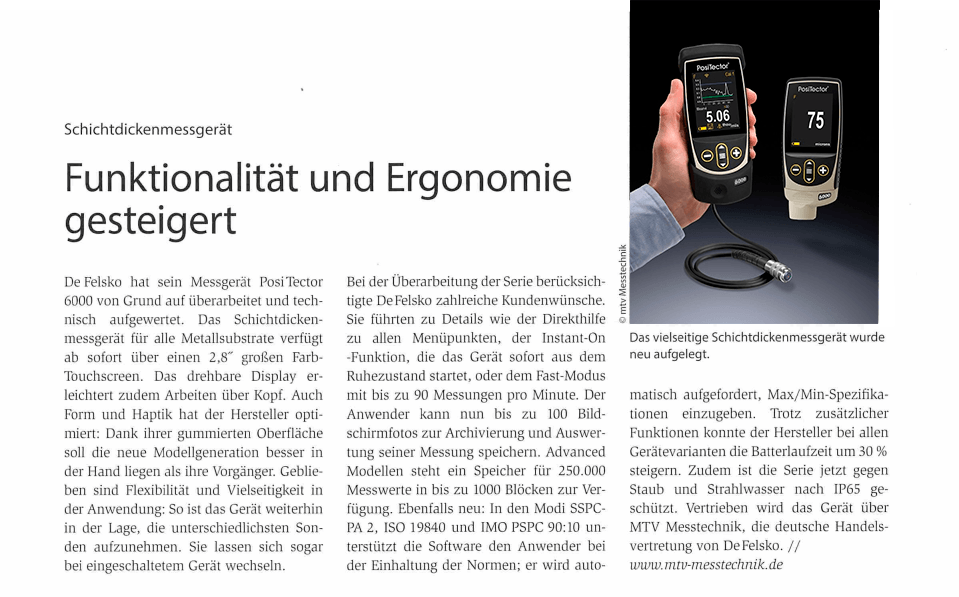

Article in JOT - Journal for Surface Technology about our coating thickness gauge for metal substrates DeFelsko PosiTector 6000

An interesting article worth reading about our coating thickness measuring device for all metal substrates PosiTector 6000 has just been published in the specialist journal JOT - Journal for Surface Technology, issue 09/2022 with the title: Increased functionality and ergonomics

New article about PosiTector 6000 coating thickness gauge published in German magazine for surface technology - mo

An article about our coating thickness gauge for all metal substrates PosiTector 6000 has been published in the renowned

magazine for surface technology - mo!

Titled "PosiTector 6000 from Defelsko with more functions", the article focuses in particular on the completely revised and much expanded range of functions of the devices.

Download the article as a PDF file here:

Article in the trade journal better painting about the PosiTector 6000

Titled "Coating Thickness Gauge with More Functions", the trade journal for industrial coating technology Besser lackieren (better lacquering) has published an article on August 18, 2022 about our coating thickness gauge for all metal substrates PosiTector 6000.

mtv messtechnik oHG is celebrating its 28th birthday!

We are celebrating 28 successful years and thank all our customers for their loyalty.

NEW features for DeFelsko PosiTector 200, PosiTector 6000 and PosiSoft software

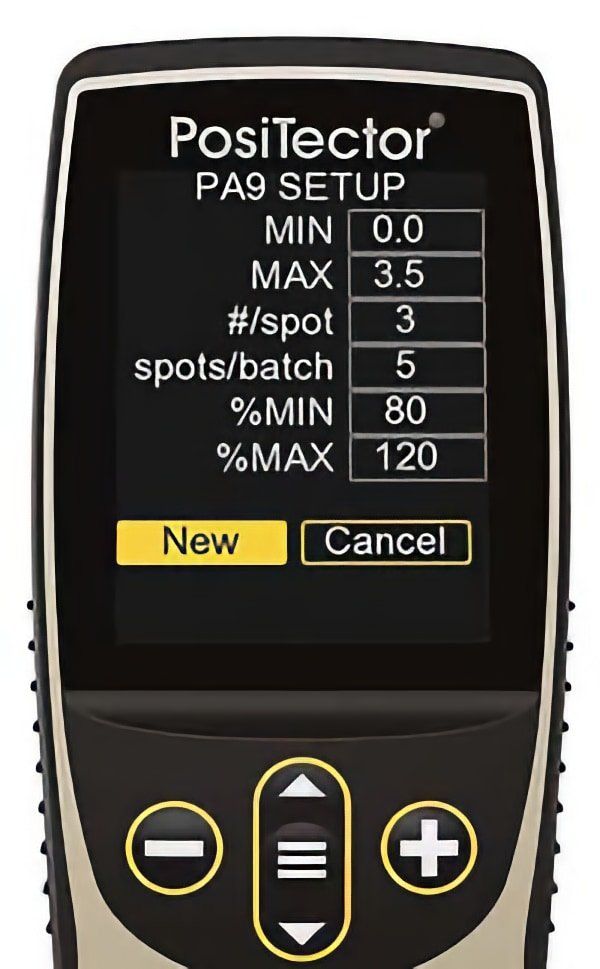

New SSPC-PA 9 mode for PosiTector 200 Advanced, a calibration adjustment feature for PosiTector 6000, and exciting new features in PosiSoft Desktop

NEW for PosiTector 200 Advanced

NEW SSPC-PA 9 mode

Similar to the SSPC-PA 2 mode of the PosiTector 6000, the SSPC-PA 9 mode for the PosiTector 200 helps clarify whether the dry film thickness conforms to the specified minimum and maximum values by prompting for the required readings and a detailed report is generated with a pass/fail analysis.

NEW Multiple saved calibration settings

Comparable to the PosiTector 6000, the PosiTector 200 now stores up to 10 calibration settings for measuring a wide variety of coating applications. Saved calibration settings can be renamed for easy identification.

Available for PosiTector Advanced models with serial numbers 864000 and higher. Updates to the device software and/or PosiSoft software may be required.

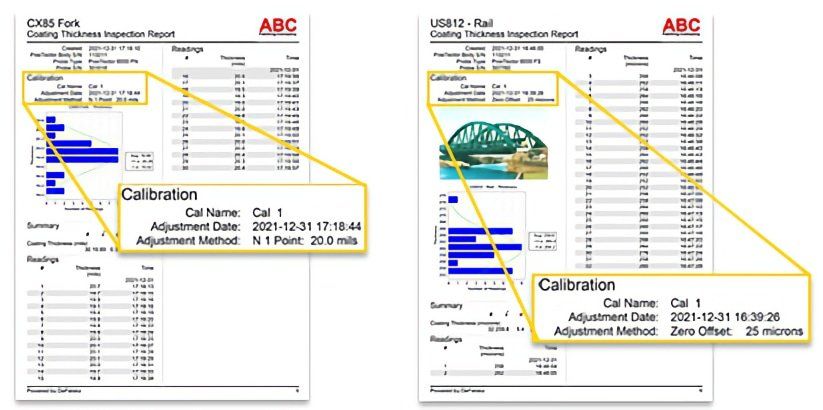

NEW for PosiTector 6000 Advanced

Reporting function for calibration settings

The new Calibration Adjustment Reports feature documents the calibration adjustments made on the PosiTector 6000 in the reports in PosiSoft software. Both the type of adjustment (factory zero point, zero offset, 1-point, 2-point) and the thickness reference value are displayed. Ideal for reports in accordance with standards such as ISO 19840. mtv messtechnik oHG

Available for PosiTector Advanced models with serial numbers 864000 and higher.

Updates to the device software and/or PosiSoft software may be required.

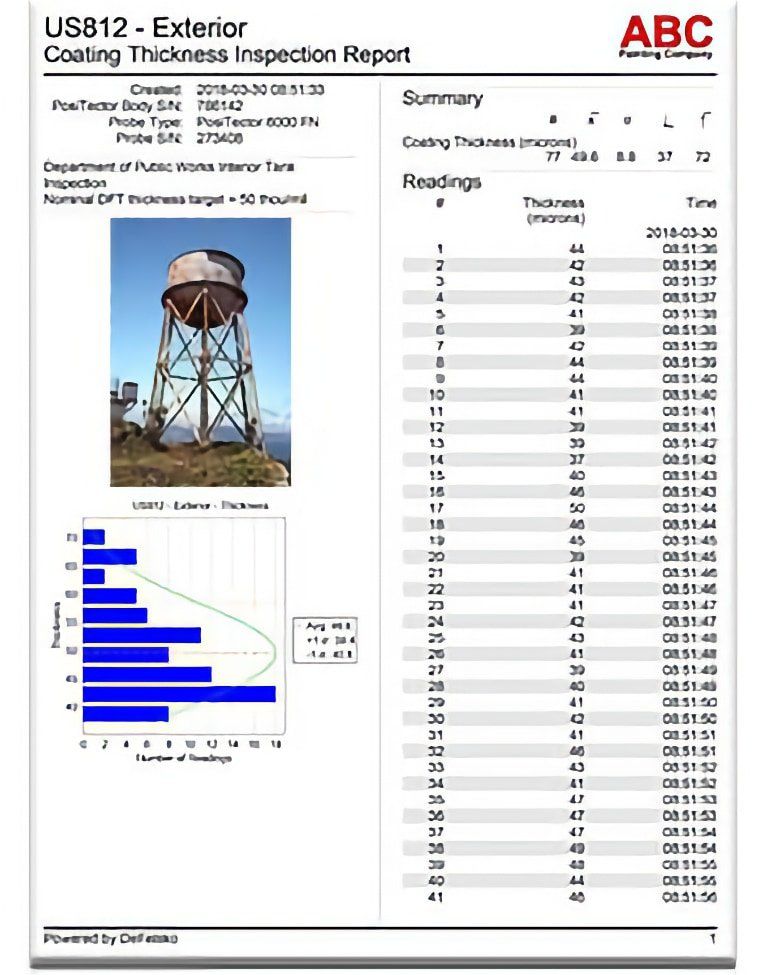

NEU in PosiSoft Desktop

Multi-column report template

A new 2-column report template is available, which is a compact alternative to the standard report template. The new template allows most typical batches to be reported on a single page without reducing font size.

A PosiSoft update may be required.

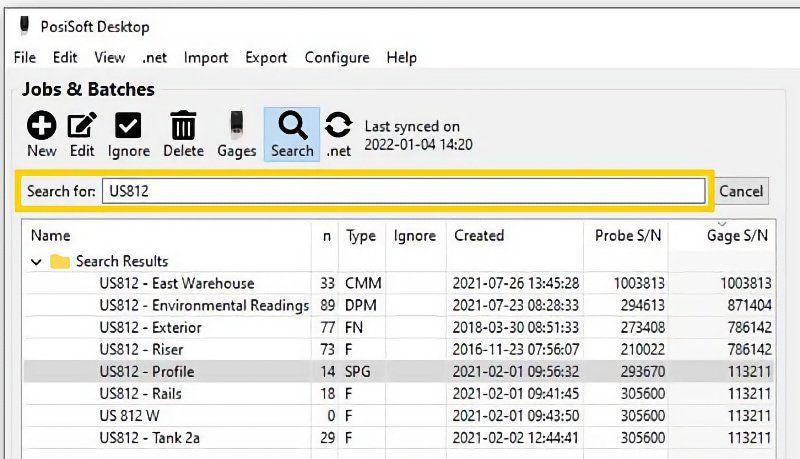

NEW function in PosiSoft Desktop

We implemented search functionality in PosiSoft Desktop

PosiSoft Desktop Software can now search for stored blocks by probe type, block name, or block note. Useful for users with a large number of blocks.

You can now find us with a detailed entry at https://www.branchenverzeichnis.org/!